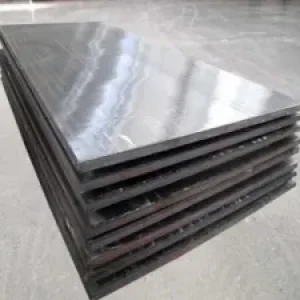

Overview of Stainless Steel/Steel Clad Plate

Stainless steel/steel clad plate is made of base steel plate and multilayer steel plate as raw materials, and the surface is smooth and flat after polishing and other treatments. The composite layer is firmly bonded, the mechanical properties are good, and the compound layer is resistant to the corrosion of atmosphere, acid, alkali and other media, which can meet the corrosion resistance requirements of the side of the structure in contact with the corrosive medium. The base layer can meet the requirements of the structure for rigidity and weldability.

Feature of Stainless Steel/Steel Clad Plate

Stainless steel/steel clad plate has both multilayer functionality and base layer strength and toughness performance. As a resource-saving product, it can reduce precious metal consumption and costs. It achieves the perfect combination of low cost and high performance, with good social benefits.

The standard method of producing clad steel is the roll cladding method. Carbon steel and stainless steel form a metallurgical bond during heating and rolling.

Hot roll bonding is a commonly used process in our stainless steel-clad plate factory. During this process, clean sheets of carbon steel and stainless steel are placed on each other (single-sided cladding) or sandwiched between two stainless steel sheets (double-sided cladding). The composite sheets are hot rolled together.

The stainless steel cladding process results in a bond between the two metals. Another manufacturing method is explosive bonding. The metals bond during the explosion due to the plastic deformation of the strong collision. Explosive bonding after the hot rolling process can improve the bond between carbon steel and stainless steel.

Composite carbon steels are used in chemical processes, oil refining, offshore oil production, and many other applications. They are also used in generator sets where high temperatures and stress corrosion are present.

Applications of Stainless Steel/Steel Clad Plate

Petrochemical, pressure vessels, Add transmission pipeline, heat exchanger, Vacuum salt production, papermaking, Beer, medicine, food, Waterpower, power station, aerospace and other fields.

- Chemical processing: Equipment exposed to harsh chemicals, such as reactor vessels, piping, and heat exchangers.

- Power generation:Boilers, turbines, and heat exchangers in power plants due to its high resistance to corrosion and high temperature.

- Marine and offshore:Shipbuilding, oil rigs, and other marine structures for corrosion resistance and improved durability in harsh environments.

- Aerospace:Aircraft components, such as engine parts, for its high strength and durability.

- Nuclear: Nuclear reactors and fuel storage containers for its high resistance to radiation and ability to withstand harsh conditions.

Company Profile

Metal Clad Builders is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality copper and relatives products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality metal Cladding Panel and processing service, please feel free to contact us or click on the needed products to send an inquiry.

Grade of Stainless Steel/Steel Clad Plate

S11306,S11348,S30408,S30403,S32168,S31603,S31703,S22053,S39042,Q245R,Q345R,15CrMoR,16Mn,15CrMo,14Cr1MoR,16MnDR,

09MnNiDR,20MnMo,SA516Gr50,SA516Gr60,SA516Gr70

Standard of Stainless Steel/Steel Clad Plate

ASME(ASTM) SA-263,SA-264

Package of Stainless Steel/Steel Clad Plate

According to product characteristics and customer needs.

Remark of Stainless Steel/Steel Clad Plate

Please provide detailed technical requirements to facilitate communication and determine the solution.

FAQ

Question: What is the corrosion resistance of stainless steel and steel composite panels?

Answer: Stainless steel and steel composite panels have excellent corrosion resistance, especially in humid, acidic or alkaline environments. They can resist the erosion of a variety of corrosive media and ensure the service life of the equipment.

Question: How strong are stainless steel and steel composite panels?

Answer: Stainless steel and steel composite panels combine the strength of stainless steel and steel, with high tensile strength and yield strength. This makes it excellent in situations where it can withstand heavy loads and high pressures.

Question: What is the manufacturing process of stainless steel and steel composite panels?

Answer: The manufacturing processes of stainless steel and steel composite panels include explosion cladding, rolling cladding and other methods. These methods ensure a tight bond between the two metal layers while retaining the performance advantages of each.

Question: How to properly install and use stainless steel and steel composite panels?

Answer: When installing and using stainless steel and steel composite panels, relevant operating procedures and safety standards should be followed. Take care to avoid scratches, impacts and excessive bending, which may affect its performance. At the same time, keep its surface clean and dry and avoid contact with corrosive substances.

Question: What are the maintenance precautions for stainless steel and steel composite panels?

Answer: Stainless steel and steel composite panels should be cleaned and inspected regularly to detect and deal with possible damage or corrosion in a timely manner. When cleaning, use neutral detergent and soft cloth, and avoid using corrosive substances such as strong acids and alkalis.